Good Hcnc 808di 3 Axis CNC Milling Controller

Description

Basic Info

| Model NO. | HCNC 808DI |

| Material | Metal |

| Certification | ISO 9001:2008, ISO 9001:2000, CE, CE, RoHS, ISO 9001, CE, ISO9001 |

| Application | Metal |

| Process Usage | Metal-Cutting CNC Machine Tools, CNC Non-Conventional Machine Tools, Metal-Forming CNC Machine Tools |

| Movement Method | Linear Control |

| Control Method | Closed-Loop Control |

| Numerical Control | CNC/Mnc |

| Processing Precision | 0.01~0.02(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Condition | New |

| After-Sales Service | Russia |

| After Warranty Service | Video Technical Support, Online Support |

| Core Components | PLC |

| Applicable Industries | Manufacturing Plant |

| Machinery Test Report | Provided |

| Weight | 8kg |

| Dimension(L*W*H) | 530*235*365 (mm) |

| After-Sales Service Provided | Video Technical Support, Online Support |

| Local Service Location | Russia |

| Marketing Type | Ordinary Product |

| Showroom Location | Russia |

| Video Outgoing-Inspection | Provided |

| Transport Package | Carton or Wooden Box |

| Specification | 530*235*365 (mm) |

| Trademark | HCNC |

| Origin | Hubei, China |

| Production Capacity | 1000000 Set/Sets Per Year |

Product Description

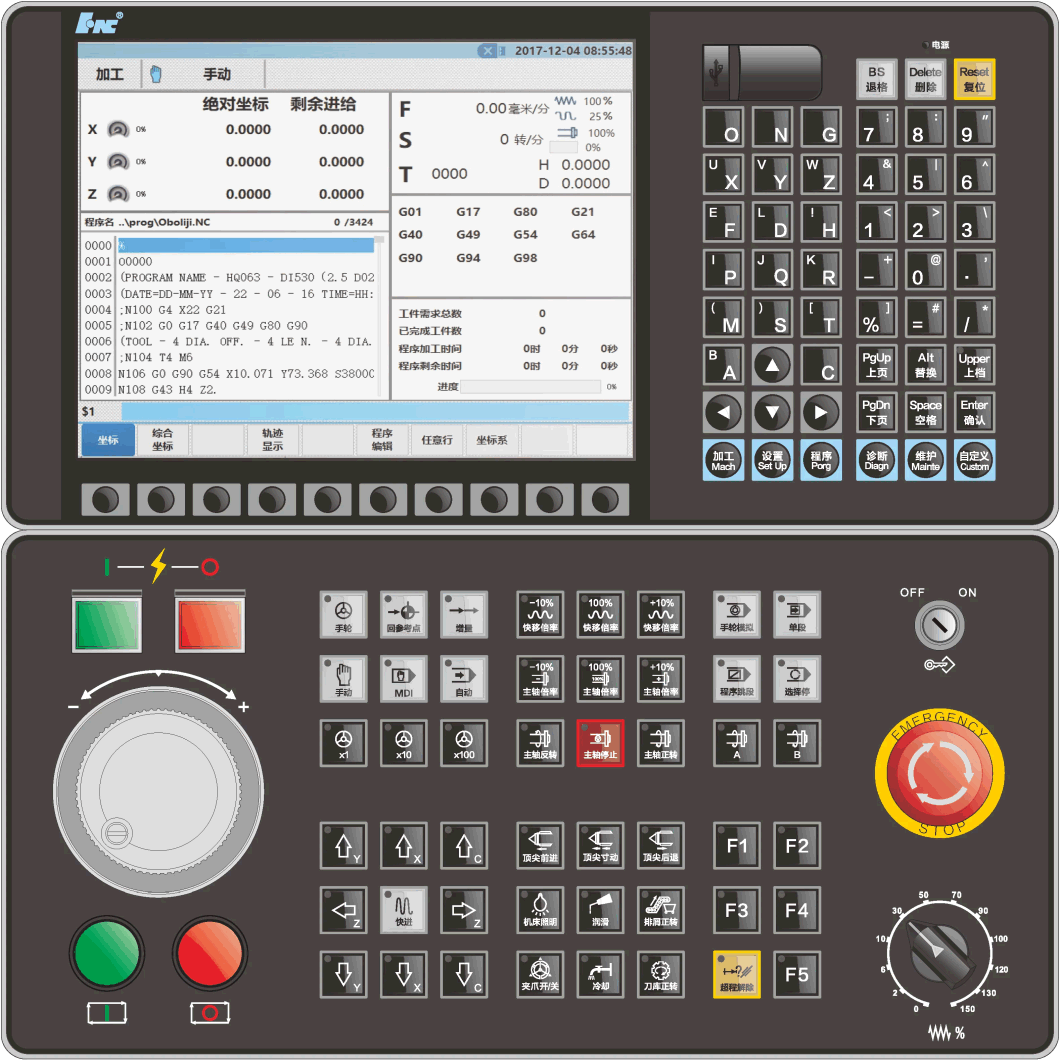

Good HCNC 808DI 3 Axis CNC Milling Controller

Products Description

HNC 808Di is our new Mill CNC Control model designed specially for small budget and can maximum control 4axis , but standard configuration is 3axis . it adopts CPU with32 bits 400MHz ARM high capacity industrial grade composing a control core, and achieves the μm level accuracy motion control. It is characterized by multiple functions, stable and cost performance CNC Controller models and easy operation; Good Choice for Universal milling machine and engraving machine.

1. 2-4 axis control; 2. 10.4" color LCD screen; 3. Supporting NCUC, etherCAT bus protocol; 4. Supporting 16,000,000PPR high-precision encoder; 5. Supporting TCP\IP, Ethernet communication protocols; 6. Supporting high-speed asynchronous motor\permanent magnet synchronous spindle motor; 7. Big data of CNC machine tool; 8. Broken tool inspection; 9. Temperature compensation; 10. 8000rpm high-speed rigid tapping (permanent magnet synchronous spindle motor); 11. Supporting bidirectional 20000 points pitch error compensation (optional); 12. Big data of CNC machine tool; 13. Broken tool inspection; 14. Machine health protection; 15. Technological process optimization; 16. Customization (optional).

More details

HNC8 high-performance CNC system, reaches the international advanced level. HNC8 is mainly used in medium and high-grade CNC machine tools such as CNC lathes, turning centers, CNC milling machines, vertical machining centers, horizontal machining centers, drilling tapping centers, and five-axis machines in the fields including aerospace, energy equipment, automobile manufacturing, shipbuilding, 3C, machine tool transformation, etc. It is the most widely used domestic high-grade CNC system. HNC8 is portable and tailorable across platforms, achieving further secondary development. It supports the processes such as laser processing, electroprocessing, and grinding, as well as the "first-generation-CNC" products such as plastic machine and printing machine. HNC8 is customizable.

Product Paramenters

Item | Specification | HNC-808 | |

M(CNC milling) | T(CNC lathe) | ||

Maximum number of simultaneously controlled axes in channel | 4 | 3 | |

Maximum number of feed axes | 4 | 3 | |

Maximum number of spindles in channel | 2 | 2 | |

Number of PMC control axes | 1 | 1 | |

Number of channels | Standard | 1 | 1 |

Maximum | 1 | 2 | |

Spindle/channel | Standard | 1 | 1 |

Maximum | 2 | 2 | |

Feed axis/channel | Standard | 3 | 2 |

Maximum | 4 | 3 | |

Maximum number of axes in simultaneous motion | 3 | 3 | |

Maximum number of feed axes | 4 | 3 | |

Maximum number of simultaneously controlled axes/channel | 3 | 3 | |

Number of input/output points at maximum | 128/128 | ||

Axis name(single channel) | Three basic axes X, Y, Z; additional axes: U, V, W, A, B, C | Standard | Not optional |

Two basic axes X, Z; additional axes: Y, U, V, W, A, B, C | Not optional | Standard | |

Axis name(multi-channel) | One or two characters plus number, the first must be a character, e.g. X1 | Not optional | Not optional |

Gantry axis synchronization | Not optional | Not optional | |

Tangent synchronization control | Not optional | Not optional | |

Basic axis coupling control | Not optional | Not optional | |

Electronic gear box | Not optional | Not optional | |

Linear chart | Not optional | Not optional | |

Inclined axis control | Not optional | Not optional | |

Minimum input unit | mm, deg, inch | 10^-3 | |

Metric/Inch | G20/G21 | Standard | Standard |

Pulse unit input | G22 | Standard | Standard |

Machine lock | Standard | Standard | |

Emergency stop | Standard | Standard | |

Overtravel | Standard | Standard | |

Spatial protection area | Providing protection for workpiece and tool | Not optional | Not optional |

Software limit | Standard | Standard | |

Dynamic axis release/capture | G101/G102 | Not optional | Not optional |

Synchronization between channels | G104.0 to G104.7 | Not optional | Not optional |

Prev: Widely Applicational CNC Milling Machine 5 Axis Controller for CNC Milling &Router Machine

Next: CNC High Speed Full Servo Unmanned Operating System for Woodworking

Our Contact