Servo drive for Metal Forming machine MDMF302L1H6M Panasonic A6 AC servo motor

Servo drive for Metal Forming machine MDMF302L1H6M Panasonic A6 AC servo motor Panasonic servo motor naming: Panasonic S

Description

Basic Info

| Certification | ISO9001, CCC |

| Transport Package | Carton |

| Trademark | STEP |

| Origin | Shanghai China |

| HS Code | 9032899090 |

| Production Capacity | 5000000 |

Product Description

Servo drive for Metal Forming machine MDMF302L1H6M Panasonic A6 AC servo motorPanasonic servo motor naming:

| MINAS A6SE, A6SG, A6SF | MINAS A6N/A6B | |||

| Position control | Control input | Clear deviation counter, pulse enable, electronicgear switching, damping control switching, etc. | Controller enable, reference signal, measurementvalue signal, etc. | |

| Control output | Position control complete, torque reached, con troller status, etc. | Position control complete, torque reached, con troller status, etc. | ||

| Pulse input | Pulse input A | 500kpps (opto coupler) | A6N: Via RTEX network (100MBit) A6B: Via EtherCAT network | |

| Pulse input B | 8Mpps (line receiver) | A6N: Via RTEX network (100MBit)A6B: Via EtherCAT network | ||

| Signal format | Differential input/square-wave pulse | A6N: Via RTEX network (100MBit)A6B: Via EtherCAT network | ||

| Electronic gear | Scaling from 1/1000 to 1000 times | |||

| Smoothing filter | First order low pass filter or FIR filter, customizable | |||

| Analog input (A6SF only) | Torque limit command | Individual torque limit for positive and negative direction | ||

| Instantaneous speed observer | Available | |||

| Vibration suppression | Manual/automatic | |||

| Velocity control | Control input | 1.-3. Selection of internal velocity setup, 4. Speed clamp, etc | ||

| Control output | Set velocity has been reached, etc | Set velocity has been reached, etc. | ||

| Analog input(A6SF only) | Velocity command | Velocity and direction | ||

| Torque limit | Available | |||

| Velocity range | 1-6500r/min | |||

| Internal velocity command | 8 velocity set values | A6N: Via RTEX network (100MBit)A6B: Via EtherCAT network | ||

| Smooth start-up and stopping | Individual setup of acceleration and deceleration from 0 to 10s/1000r/min,S-curve acceleration/deceleration ramp possible. | |||

| Zero speed clamp | Speed clamp input | |||

| Instantaneous speed observer | Available | |||

| Velocity control filter | Available | |||

| Torque control | Control input | Speed clamp input, "Torque under control" input, etc. | Reference signal, limit switch evaluation, etc. | |

| Control output | Set torque has been reached (at predefined ve locity), etc. | Set rotation speed reached, torque reached, etc. | ||

| Analog input | Velocity command | Set speed can be scaled | ||

| Speed limit function | Speed can be scaled | |||

| Full-closed control | Control input | 1. Reset counter, 2. Command pulse inhibition,3. Electronic gear 4. Filter switching | ||

| Control output | Position control complete (in position) | |||

| Pulse input | Opto coupler (pulse in put A) | 500kpps | ||

| Line receiver (pulse in put B) | 4Mpps | |||

| Signal format | Differential input/square-wave pulse | |||

| Electronic gear | Scaling of pulse frequency from 1/1000 to 1000 times | |||

| Smoothing filter | First order low pass filter or FIR filter, customizable | |||

| Analog input | Torque control | Torque limit available | ||

| Vibration suppression | Manual/automatic | |||

| Scaling of counter pulses | From 1/40 to 160 times | |||

| Other features | Autotuning | Automatic adjustment of the driver's rigidity to the vibration behavior of the mechanical parts and changes to the load. | ||

| Encoder resolution | Any value up to the maximalresolution of the encoder | |||

| Protectivefunction | Error messages causing switch-off | Overvoltage, undervoltage, overspeed, overload, overheat,overcurrent, encoder error, etc. | ||

| Error messages requiring acknowledgement | Exceeding the position deviation, command pulse division error, EPROM error, etc. | |||

| Alarm history | Can be logged for reference | |||

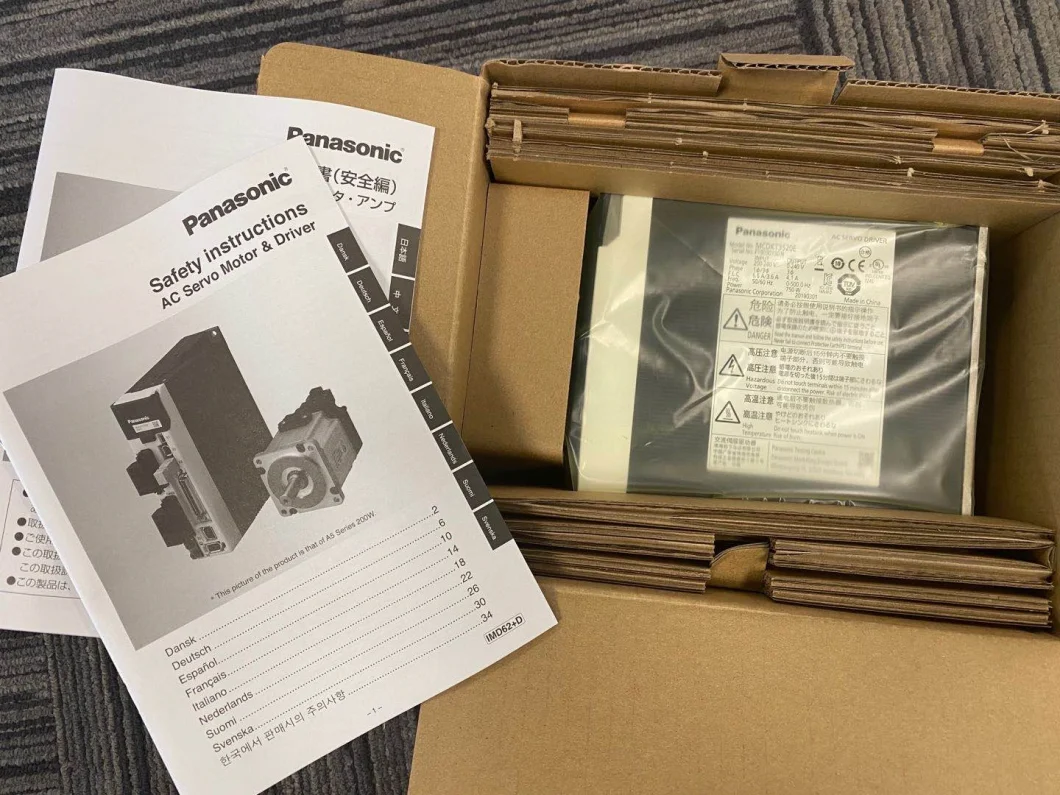

Panasonic Servo & motor &PLC packing:

Panasonic Factory:

Prev: 2022 High Quality 4 Axis Mach3 CNC USB Controller for CNC Milling Machine

Next: Vocational Training Equipment Teaching Equipment Servo Break and Drive System

Our Contact

Send now